Mastering Adhesive Processes: From Selection to Seamless Integration

Are you in the process of planning or improving an adhesive dispense application?

Are you looking to automate a manual dispense process for improved accuracy, repeatability, efficiency or to support volume ramp?

Or perhaps you need support deciding if an advanced vision, part placement, or dispense technology will yield greater results?

In today’s ever-evolving manufacturing landscape, adhesive bonding is vital to ensure robust and dependable assemblies across numerous industries. However, achieving optimal adhesive performance demands careful attention to many factors, including adhesive selection, dispensing accuracy, process automation, and seamless system integration.

Thankfully, you don’t need to be an expert in dispensers, pattern design, needle contact options, or vision system programming… that’s our wheelhouse; that’s what we do for you.

We have many experiences across industries, including medical devices, consumer electronics, and cutting-edge R&D platforms.

Design & Technology Integration for Automated Adhesive Dispense

AC can help you with the multiple critical design decisions that can have a significant impact on the quality, repeatability, efficiency, and management of your adhesive dispense operation.

> Selecting the right dispense and curing technologies whether it be 1-part, 2-part, contact, or jetting dispensers

> Integrating advanced robotics and motion control to achieve the targeted degree of accuracy and part placement you need

> Integrating advanced vision and inspection systems to dispense onto a wide range of parts, surfaces, contours, and geometries

> Reducing manual maintenance procedure overhead by automating and monitoring common dispense cleaning, changeout, and needle find procedures

Selecting the Right Adhesive Dispense & Curing Technologies

Choosing the appropriate curing method is a critical aspect of adhesive selection, as it directly impacts the strength, durability, and performance of bonded assemblies. The curing process transforms adhesives from liquid or semi-liquid to solid, creating strong bonds. Several factors must be considered when selecting the proper curing method.

Firstly, understanding the adhesive’s curing mechanism is essential. Adhesives can cure through various methods such as chemical reactions, heat, UV light, moisture, or a combination of these.

Each method also has its requirements and considerations. For instance, heat curing may involve subjecting the adhesive to specific temperatures for a designated period, while UV curing utilizes ultraviolet light to initiate and complete the curing process rapidly.

Andrews Cooper Engineers:

> Consider the strengths and weaknesses of contact and jetting dispense technologies and vendor support experiences

> Select the right adhesives, curing methods, and contact types with corresponding dispense tips (needle vs nozzle) to achieve very fine dispense patterns and adhesive lines with high precision, down to 200 micron beads

> Automate to achieve higher levels of accuracy, repeatability, and dispense performance

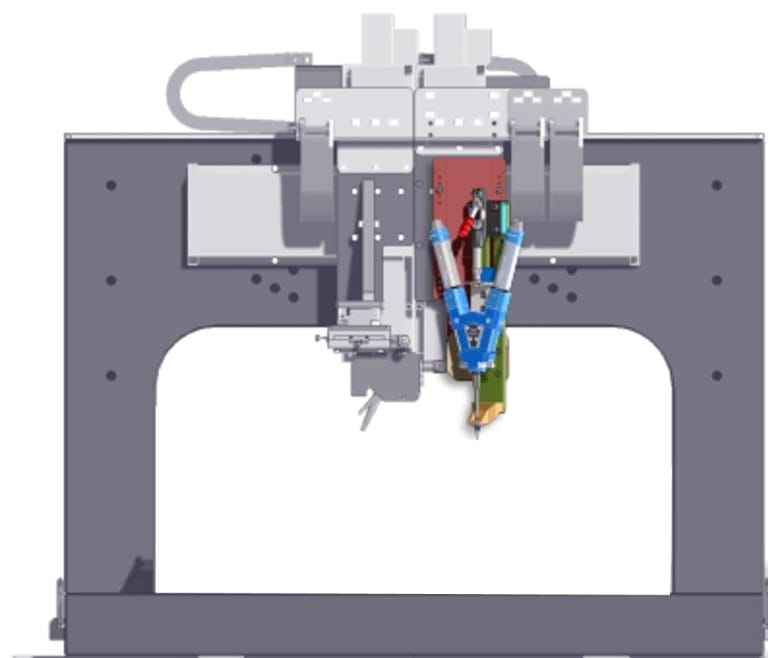

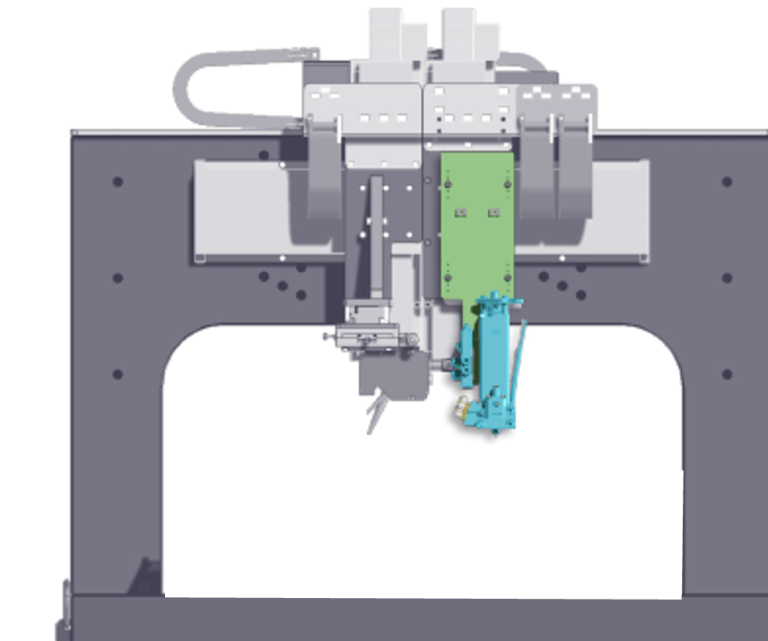

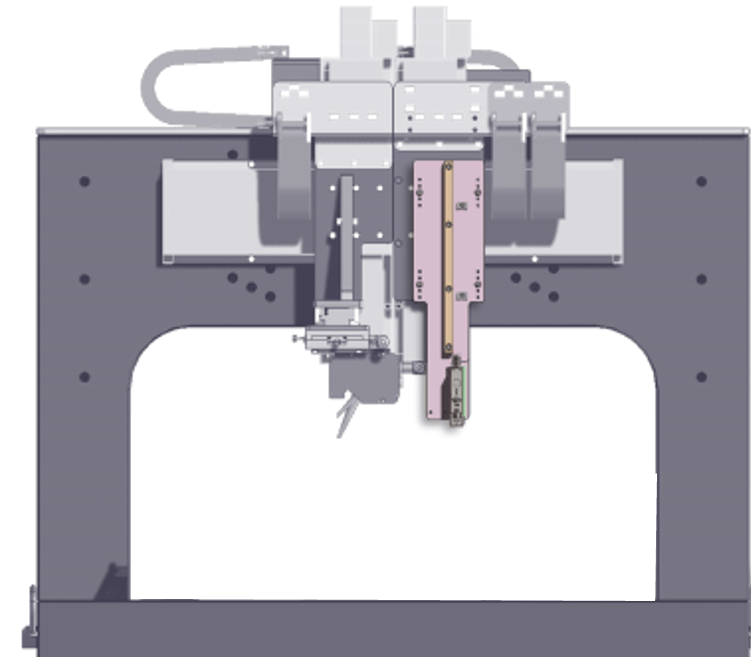

Integrating Advanced Robotics & Motion Control

For highly precise or complex dispense objectives, sophisticated motion control must ensure that part positioning, placement, and movement are coordinated perfectly with the dispensing process.

By integrating the adhesive dispense system with the overall control system of the production line, manufacturers can achieve synchronized and coordinated operations. This integration allows for real-time communication, data exchange, and control signals between the adhesive dispense system and other equipment, such as assembly stations or curing ovens.

Incorporating robotics into adhesive dispense systems brings a new level of accuracy, repeatability, and flexibility to the process. With programmable motion control, robots can precisely control the dispensing path, nozzle positioning, and dispense parameters, ensuring accurate and repeatable adhesive application.

Working from your requirements, we help you achieve the targeted degree of accuracy for part placement.

Andrews Cooper Engineers:

> Extrapolate a manual process to a targeted automated solution that achieves your objectives

> Leverage appropriate robotics for your targeted dispense objectives, achieving fine dispensing with high precision

> Integrate a motion control system to achieve fully coordinated movement of linear and rotational axes

> Modify an existing automated cell with improved robotic

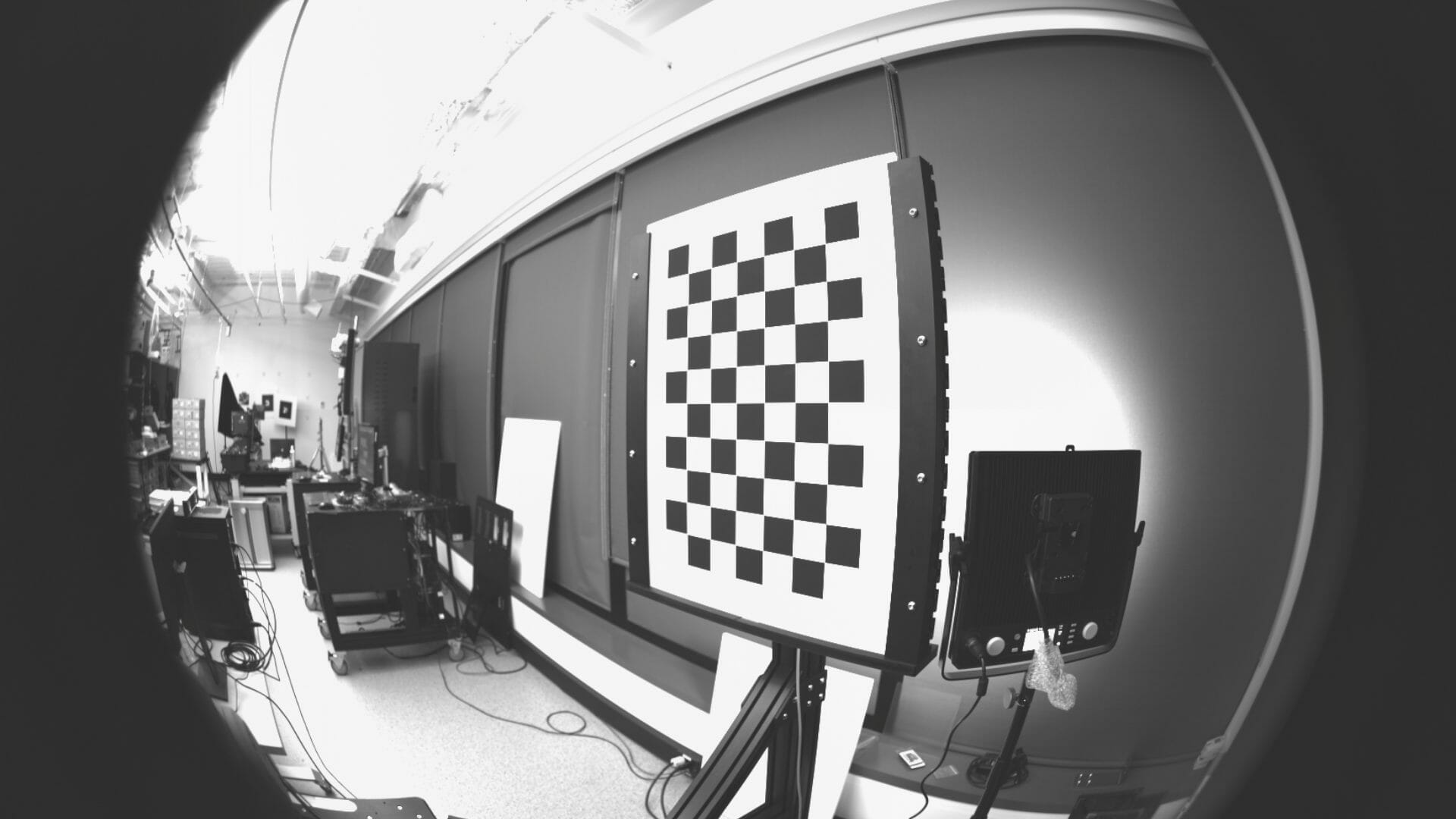

Integrating Advanced Vision & Inspection Systems

The integration of advanced vision and inspection systems into adhesive dispense processes has become a game-changer, significantly elevating the quality and reliability of bond formation. By integrating vision systems, manufacturers can ensure precise alignment of dispense paths and patterns, detecting any deviations or errors that may compromise bond strength.

These systems can also identify issues such as air bubbles, voids, or uneven dispense, allowing for immediate corrective actions. The real-time feedback provided by vision systems empowers operators to make adjustments on the fly, ensuring consistent, high-quality adhesive application and minimizing the risk of defects or rework.

Andrews Cooper Engineers:

> Select the right vision technology for your specific application, including profilometer laser scanners and high resolution camera systems

> Configure vision systems to accurately locate and scan parts and surfaces, from 2D to 3D scanning

> Coordinate and integrate vision systems with motion and dispense systems for dispense operations onto parts, surfaces, contours, and geometries

Reducing Manual Maintenance Procedure Overhead

One of the most common and time-consuming challenges we hear about is the high level of maintenance required for adhesive dispense manufacturing.

Automation plays a crucial role in reducing manual overhead and enhancing the efficiency of adhesive dispense operations. By integrating automated systems, such as robotic arms or gantries, manufacturers can automate repetitive tasks, such as adhesive dispensing or nozzle cleaning, eliminating the need for manual intervention and reducing the associated labor costs.

Andrews Cooper Engineers:

> Integrate automated dispense tip cleaning to reduce maintenance and improve uptime and operational efficiency

> Automate a needle finding program to make dispense tip replacement quick and easy

A Partner for Your Automated Adhesive Journey

Selecting the right adhesive and optimizing an automated adhesive dispense process are crucial steps in achieving successful bonding outcomes. By carefully considering factors such as adhesive properties, substrate compatibility, dispensing accuracy, and system integration, your team can overcome challenges and develop reliable automated adhesive dispense systems. The selection of an appropriate adhesive ensures compatibility with the substrate materials, while dispensing accuracy guarantees precise and consistent adhesive application. Process automation and system integration streamline production workflows, enhance efficiency, and enable seamless coordination with other manufacturing equipment.

Andrews Cooper has the technological experience and automation expertise you get you moving forward!