Selection of Engineering Materials for Premium Products

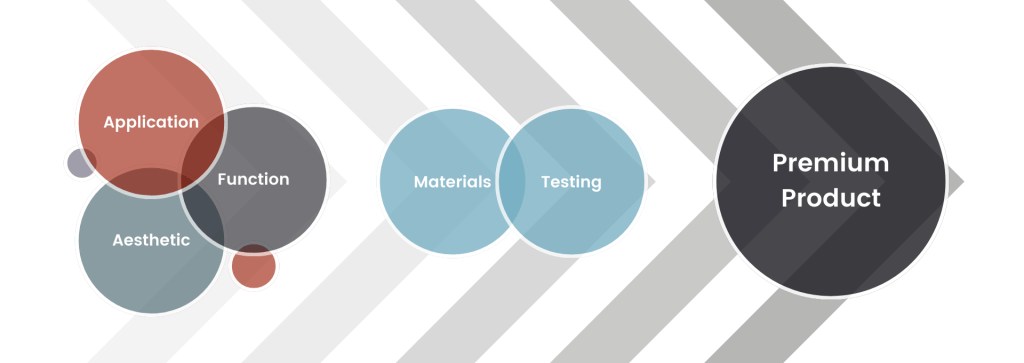

Behind your product vision are many interdependent engineering material and product design decisions for successful injection molding and product development outcomes.

What material decisions distinguish premium product designs from the rest?

In our experience, premium products leverage a holistic decision-making process to ensure the right design materials are selected with all requirements in balance. It’s where leveraging the extensive experience of a product development and materials engineering partner can ensure that your premium product is realized – perhaps even better than you imagined.

Andrews Cooper can guide you through a comprehensive approach to selecting engineering materials, design improvements, and injection molding processes for your premium product. We work closely with you to balance your application, functional, and aesthetic requirements in order to pinpoint materials and techniques.

Our highly experienced development teams work with you to achieve functional, precise, scalable, not to mention beautiful results. We have decades of success creating high-performance products for Fortune 100 brands that are in the hands of millions of customers each day.

Today, we explore our approach to some of the key material considerations and decisions at a high level. We introduce the types of injection molding materials, properties, and techniques that achieve specific outcomes.

Starting at the End to Selecting Engineering Material Requirements

Solving the challenge of engineering material selection for a premium product involves on a complex set of interdependent decisions. Where do we begin to make those decisions? At the end, of course. We start by understanding the vision you have for your completed product – your market requirements.

Understanding your market to identify your requirements

What industry are you in, who are your customers, and what are your application requirements? Will your industrial design and artwork be highly prioritized? Or will your product’s resilience or sustainability take center stage? These and other questions directly affect the materials that might be suitable for your premium product. It’s critical to understand not only your product’s aesthetic appeal and industrial design objectives, but also its functionality, industry, customers, and use environment.

For example, to identify the engineering material requirements for MedTech products, the market requirements tend to include:

> Materials that deliver clean, sophisticated industrial designs that have a harmonious appeal to both professional caregivers and patients

> Materials that are biocompatible and deliver a comforting visual, tactile, and acoustic experience for the patient

> Materials that hold up to the rigors of daily patient care, disinfection, extreme autoclave sterilization temperatures, and applied chemicals or substances during use

> Materials that enable seamless integration of advanced electronics and technology design features without impeding connectivity, structural integrity, or comfort

We work closely with you to understand and prioritize your unique market requirements which will drive your product’s material requirements.

Market Requirements

Application

> Consumer

> Industrial

> Medical

Performance

> Mechanical function

> Manufacturability

> Special requirement

Aesthetics

> Visual appeal

> Tactile and ergonomics

> Acoustic appeal

Sustainable lifecycle

> Useful life of expectancy

> Sustainability

Material Considerations

>Aesthetic: color, adhesion

> Compatibility: environmental, chemical

> Regulatory: flammability, biocompatibility

> Strength: yield, fatigue, creep

> Tribological: friction, wear

> Moldability: shrinkage, viscosity

> Additives: electrostatic discharge (ESD), antimicrobial, fibers

> Surface finish: texture, friction, grip

> Adhesion: TPE 2nd shot, paint, printing

> Sound dampening: loss modulus, hardness

> Strength/combability

> High PCR or regrind content

> Recyclability and replaceability

> V&V testing