We love a good teardown as much as the next geek – so with our expertise in end-to-end hardware product development, we were excited to look beyond the technical components of the Nintendo Switch Joy-Cons to find what was hidden under the security screws.

Controller Design in Focus

First things first… Why the Nintendo Switch? And why the Joy-Con?

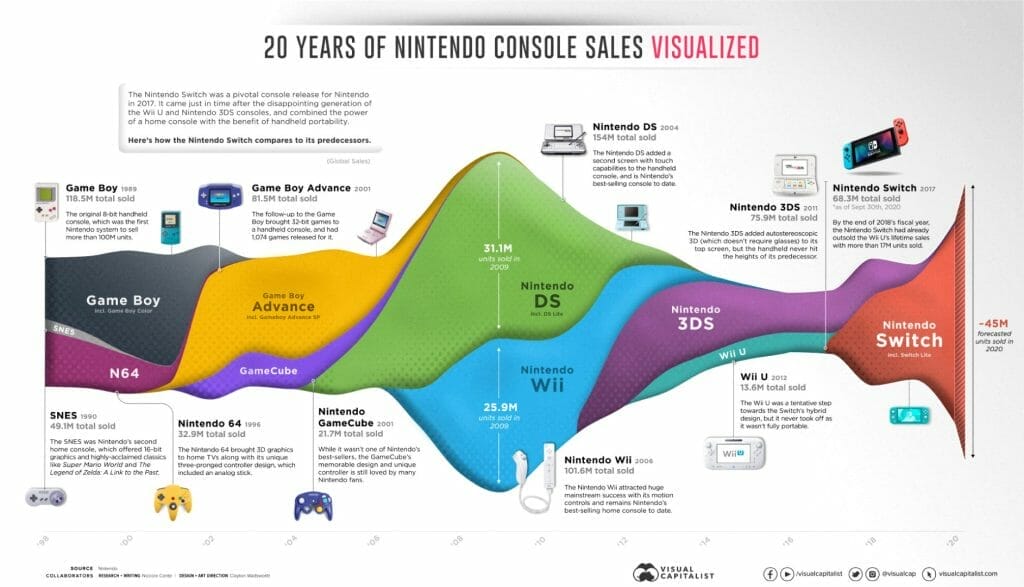

Occupying a space where technologies can quickly become outpaced by newer tech, you’d think that five years after its release, the Nintendo Switch might already be outdated, just a tick mark on the gaming tech innovation timeline. And yet this console continues to score big in consumer brand awareness around the globe, surpassing $85 million in total unit sales by 2021.

There’s plenty of analysis out there already on the design of the console, so we thought the Joy-Con was actually an interesting teardown choice. After all, the unique functionality of the Joy-Con controllers offers some intriguing design challenges.

Even though evaluating a finished product creates some constraints from a technical standpoint (we can’t identify every important decision that went into the design), our engineers at Andrews Cooper wanted to identify what clearly aided system integration, mechanical and electrical collaboration, high volume product development, and design for manufacturability (DFM).

So, what did we find? Let’s take a look!

Speak with an Engineer Today

System Integration

With just a cursory inspection, you can’t miss (or help to admire) the unique and innovative multi-use controller design of the Joy-Con.

Traditionally there have always been two main use cases for console controllers:

A) Controllers that are integrated to a display

B) Standalone controllers

But the Nintendo design team seems to have pushed for a third category:

C) Controllers designed to fully operate both independently or in tandem together

It’s a noteworthy engineering decision because in order for the Joy-Con controllers to work effectively at all times, whether connected or separated, the design required strong duplication and full system development.

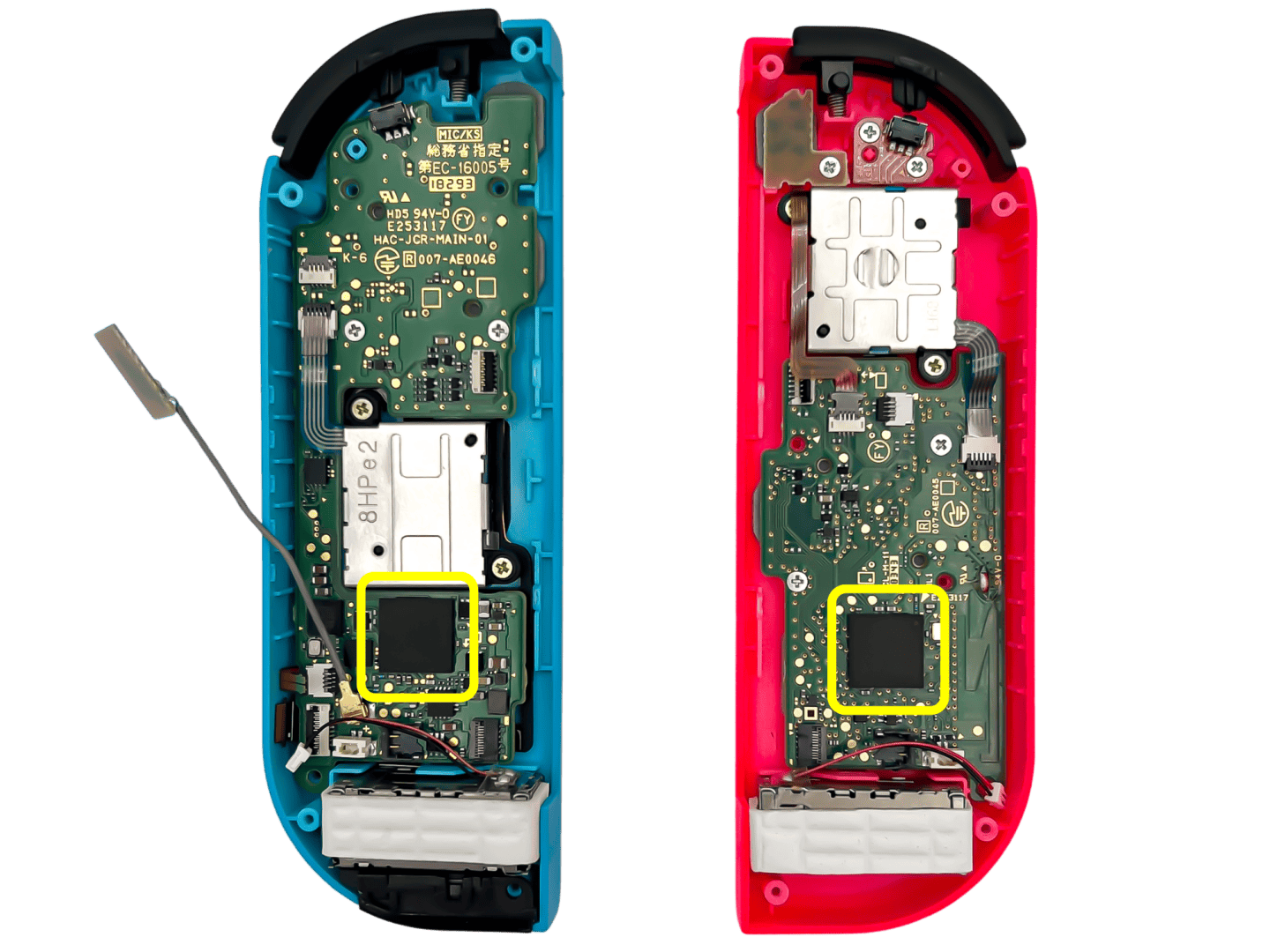

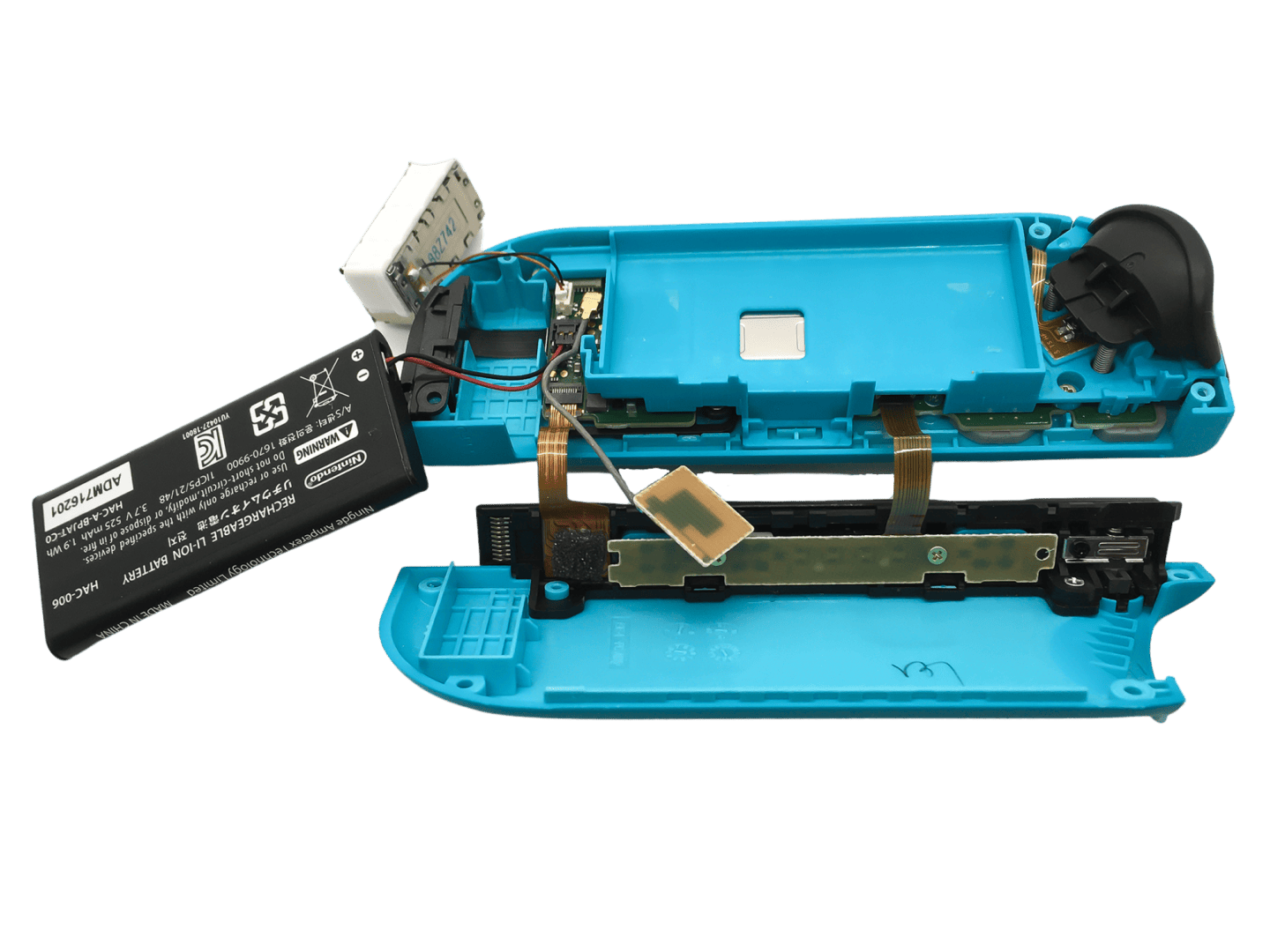

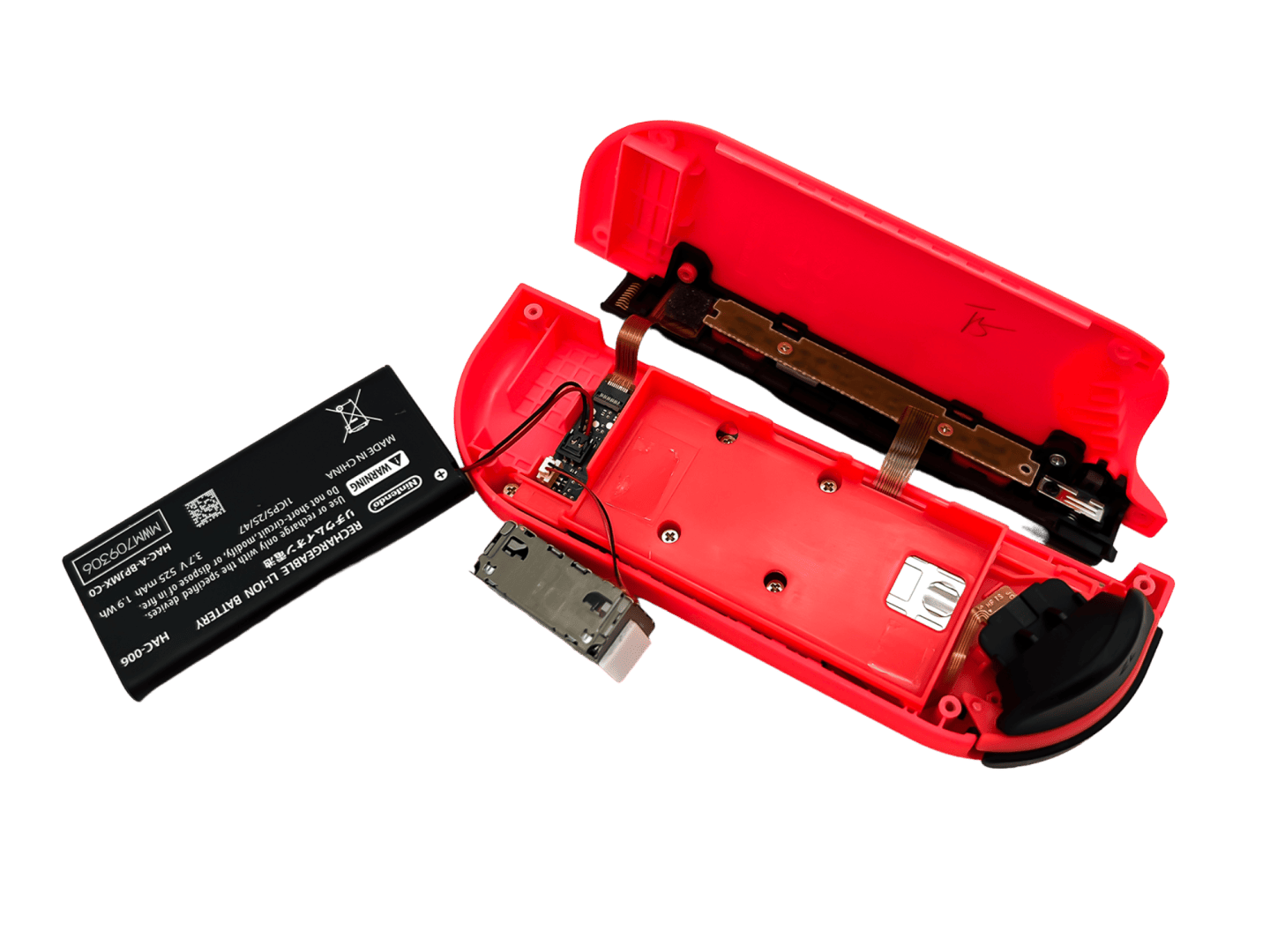

Duplication of whole system for this dual purpose also forced a key cost/benefit decision to produce a controller with dual processors, dual batteries, dual memory, dual everything.

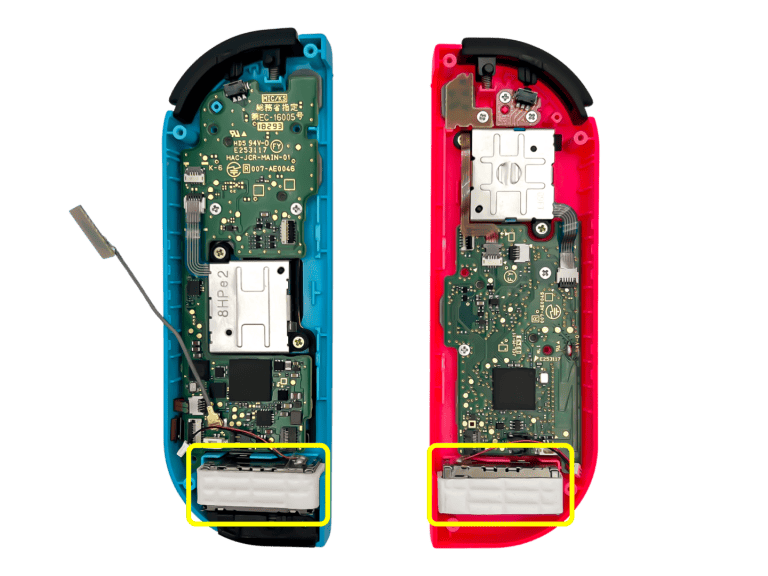

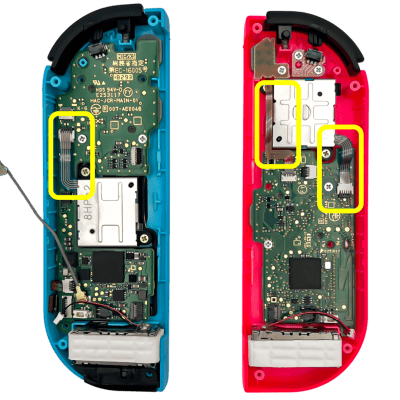

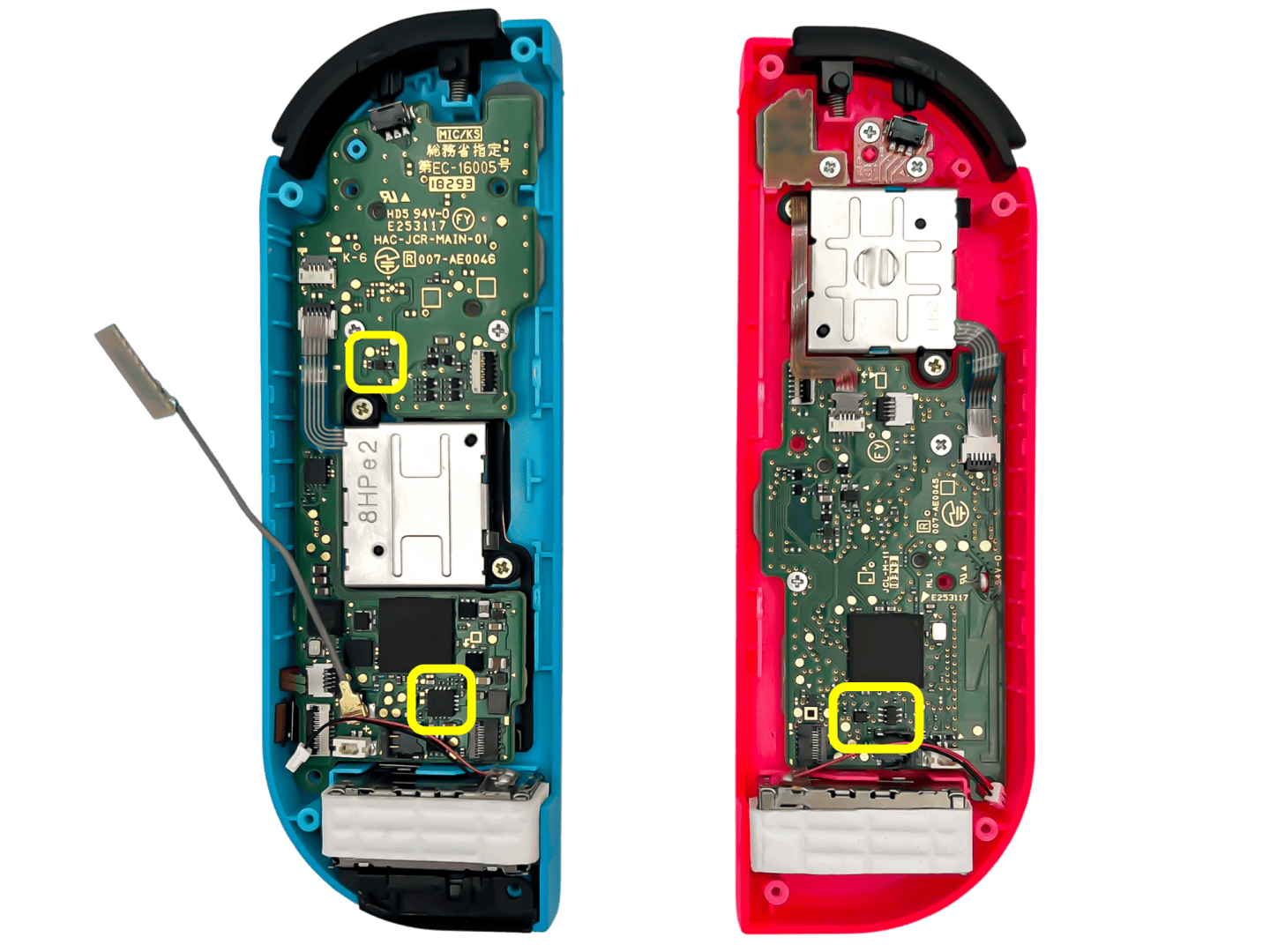

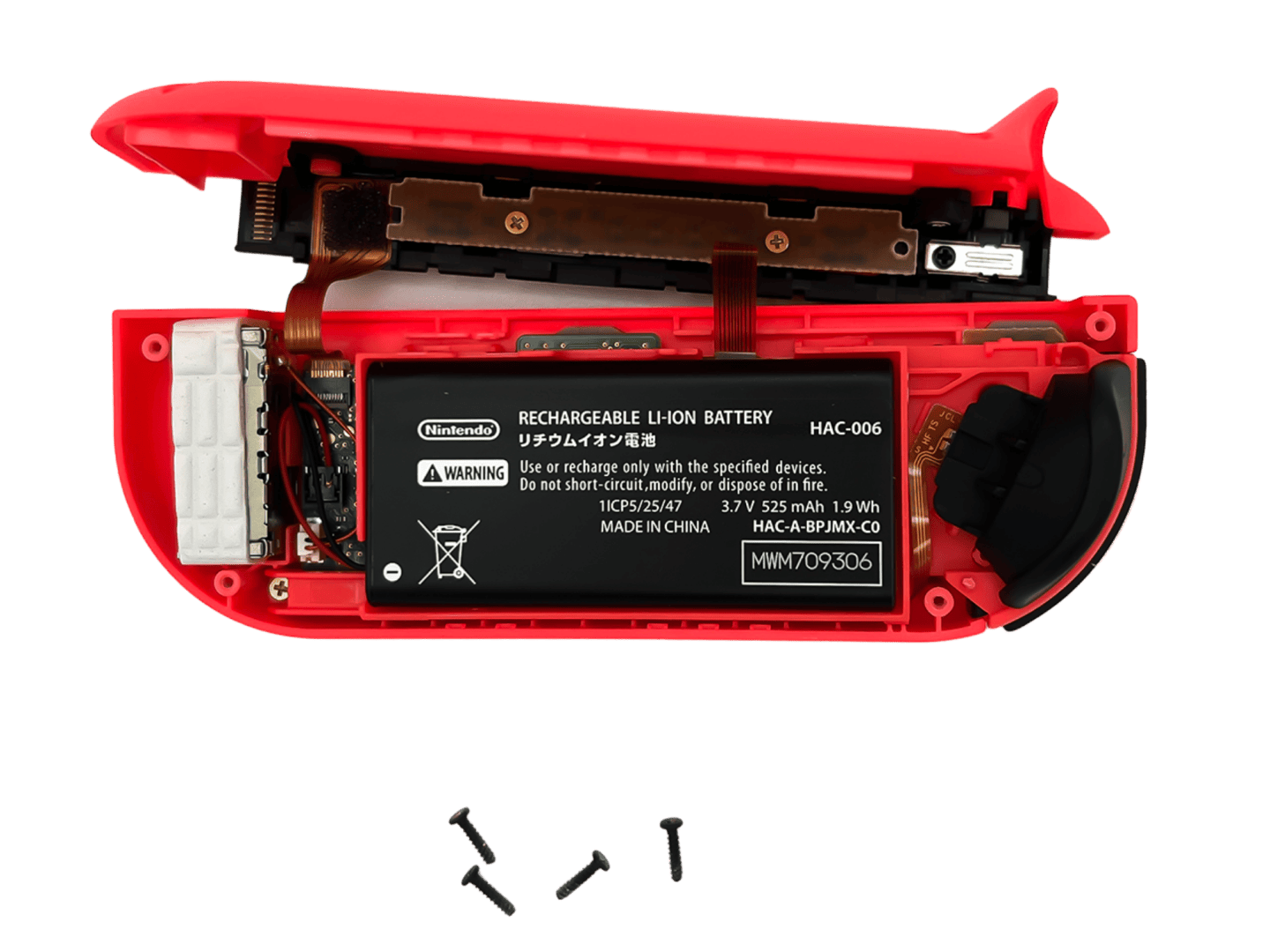

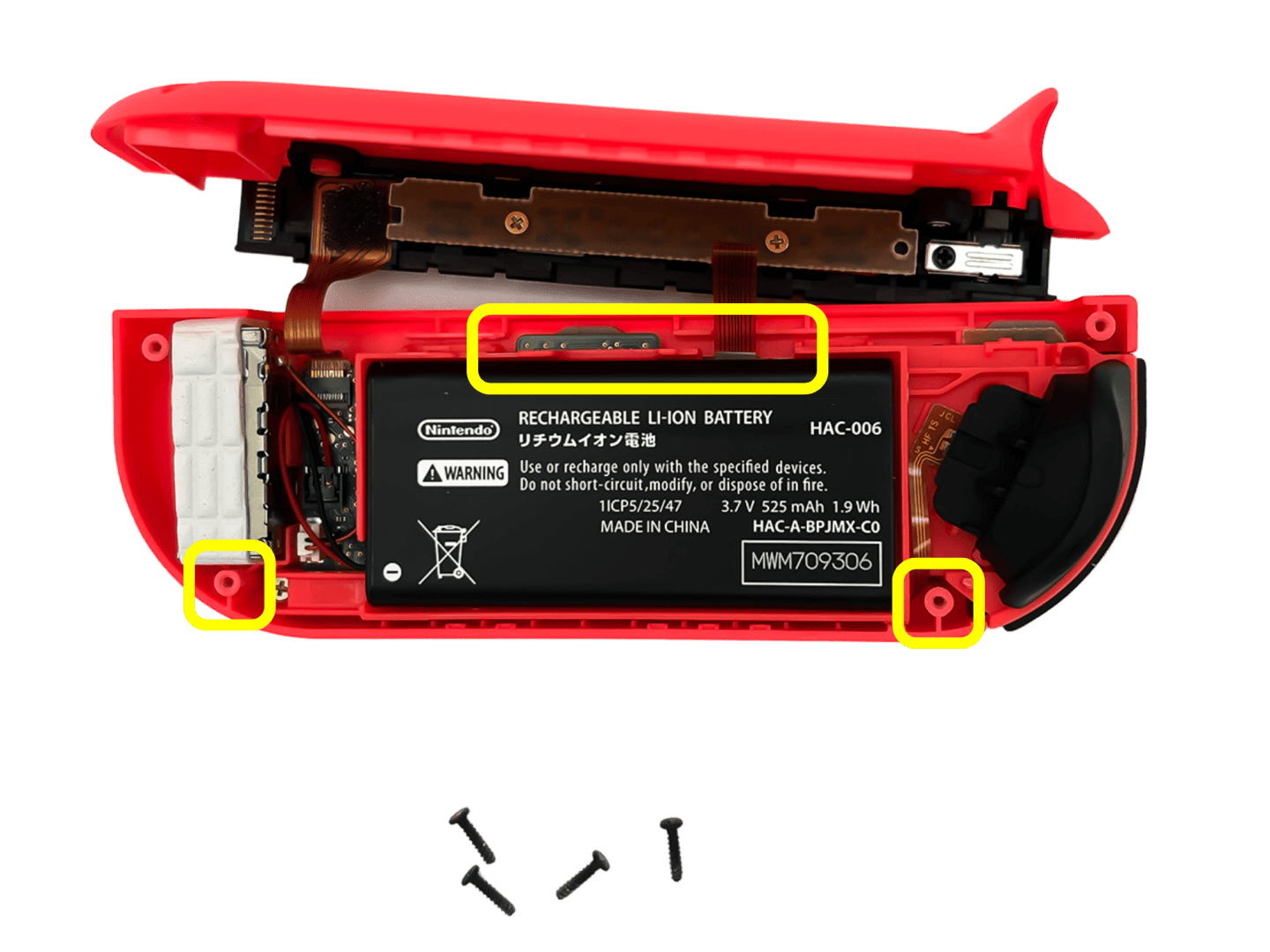

When our engineers cracked the seal on the Joy-Con controllers for a closer inspection of the dual system integration, they noted the similarities between the left and right sides of the controller, but also observed some key functional differences:

- Each left and right controller utilizes its own CPU, memory, lithium ion battery, battery management chip, thumbstick, inertial measurement unit (IMU), linear resonant actuator (LRA), and haptic driver.

- However, only the right controller includes a near-field communication (NFC) reader and infrared (IR) camera.

Particular interest is the proximity of the IMU relative to the haptics, which can be tricky to place because of their competing needs and required drivers. The Joy-Con manages this challenge through these components and design choices:

- The IMU (TDK IM-20600) has an integrated 3-axis gyroscope and a 3-axis accelerometer to deliver accurate positional and rotational measurements.

- Each LRA (Alps Reactor) enables precise software control of the frequency signal that produces the vibration of both the X and Y axis.

- By applying a firmware notch filter to the mechanically coupled IMU and LRAs, the engineers were able to cleverly filter out the LRA resonant frequencies at 160Hz and 320Hz to prevent the IMU from getting overwhelmed each time a haptic is activated.

- To reduce the chip count and computational load required by the MCU (and reduce the overall power draw of the controller), they added an integrated analog-to-digital converter (ADC).

The thoughtful design and interplay between these key components clearly had an important impact on the performance and usability of the Joy-Con controllers – it’s a great example of system integration done right.

Electrical & Mechanical Design Coordination

Controllers, like all consumer electronics, are routinely tested at different stages of the product development lifecycle to ensure they hold up to hundreds of millions of life cycles. The Joy-Con controller was no exception. With a successful worldwide distribution as hindsight, the success of the Joy-Con proves it was clearly designed and tested to achieve a level of durability that holds up at a large scale.

For any product to reach these standards of performance, experience teaches that a high level of coordination between electrical and mechanical engineers is essential. Development teams must integrate their designs for form, fit, and function in order to:

- Achieve greater performance and reliability

- Create smaller and denser subassemblies

- Conform wiring/cabling to the physical shape and limitations of the design

- Make careful choices about components to reduce costs and streamline BOMs

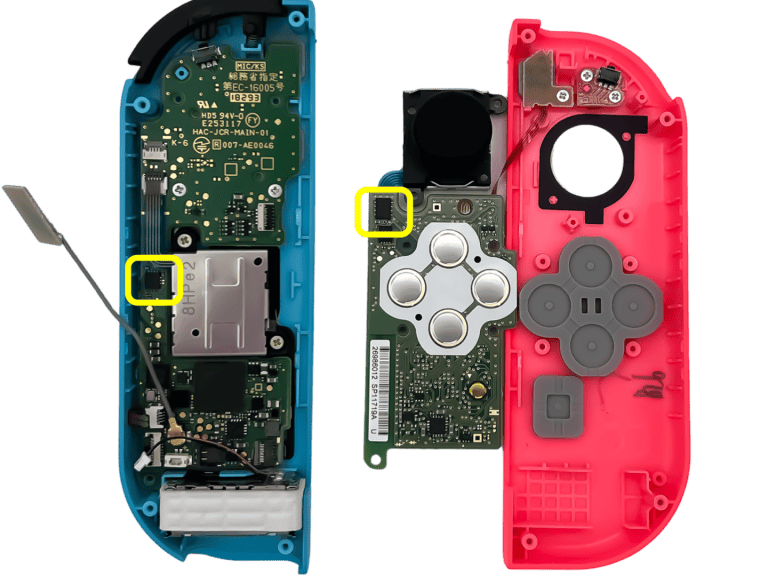

Inside Joy-Con controllers, there is clear evidence of these kinds of coordinated decisions:

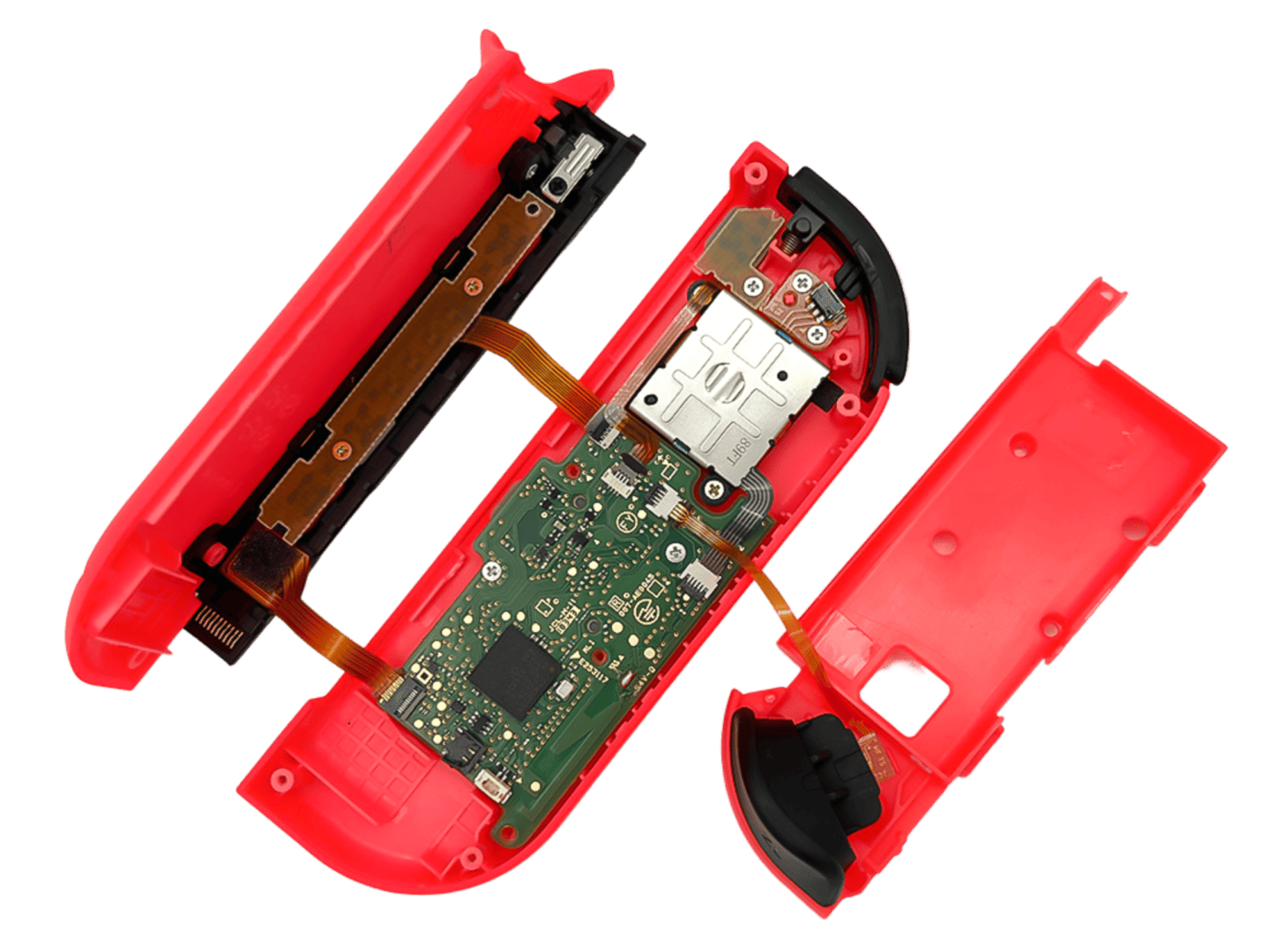

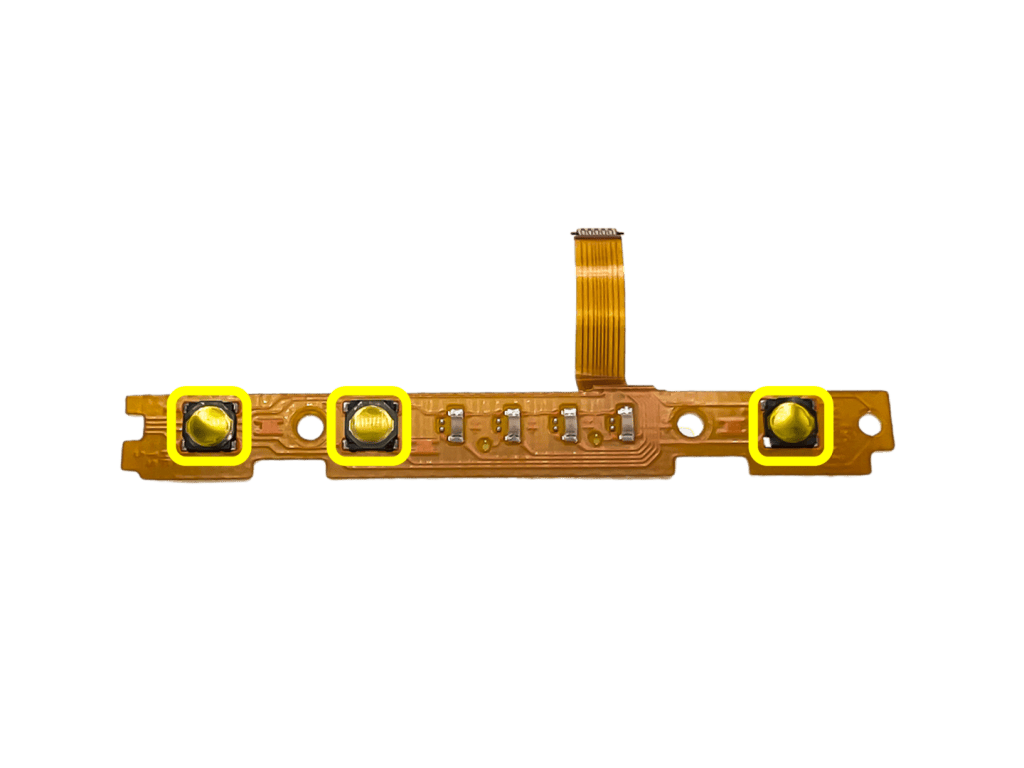

Utilization of flexible printed circuits (FPCs) results in higher reliability by eliminating a connector while providing a direct connection to one side

Use of a predefined shape reduces the need for cable routing during manufacturing

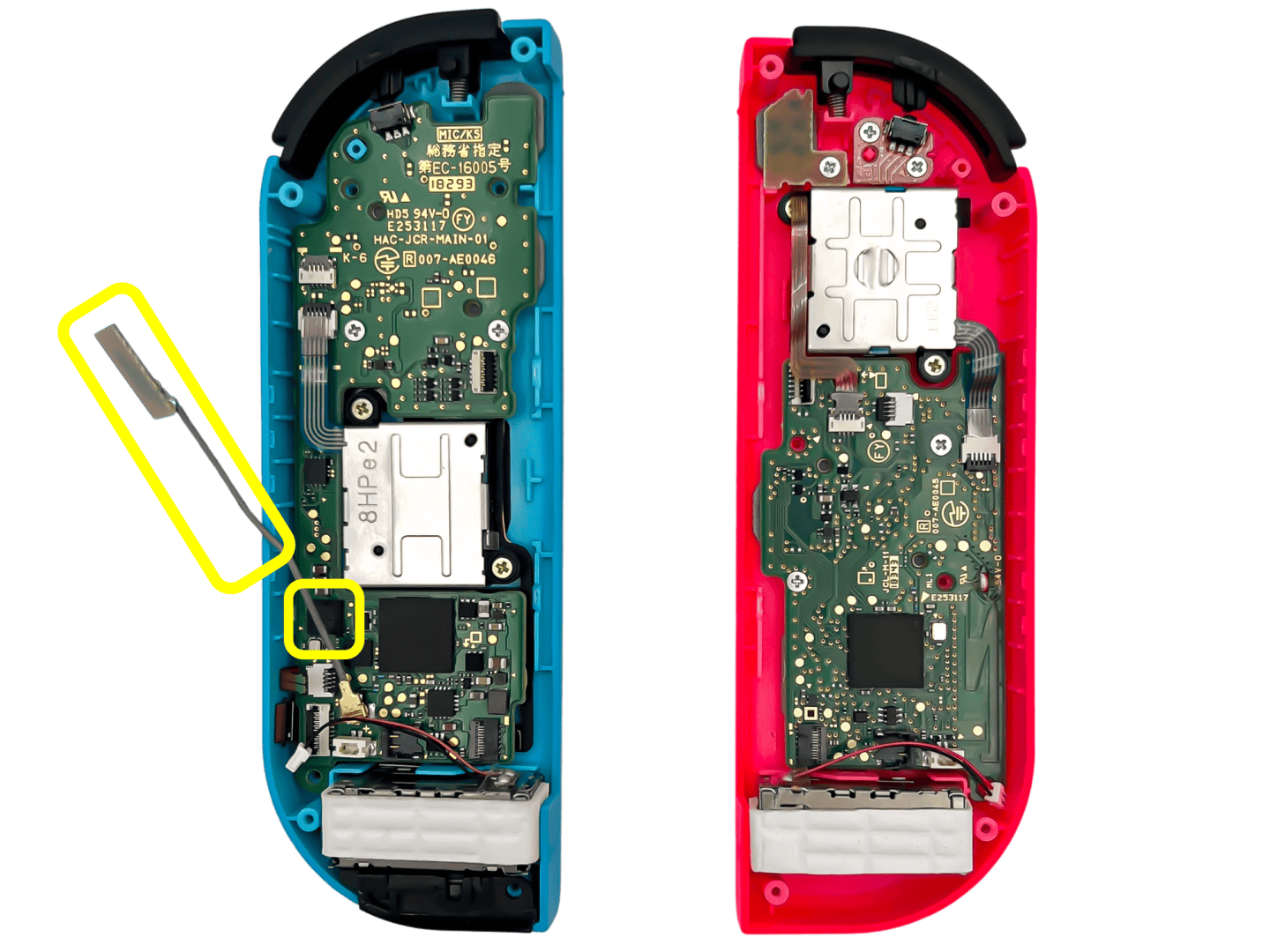

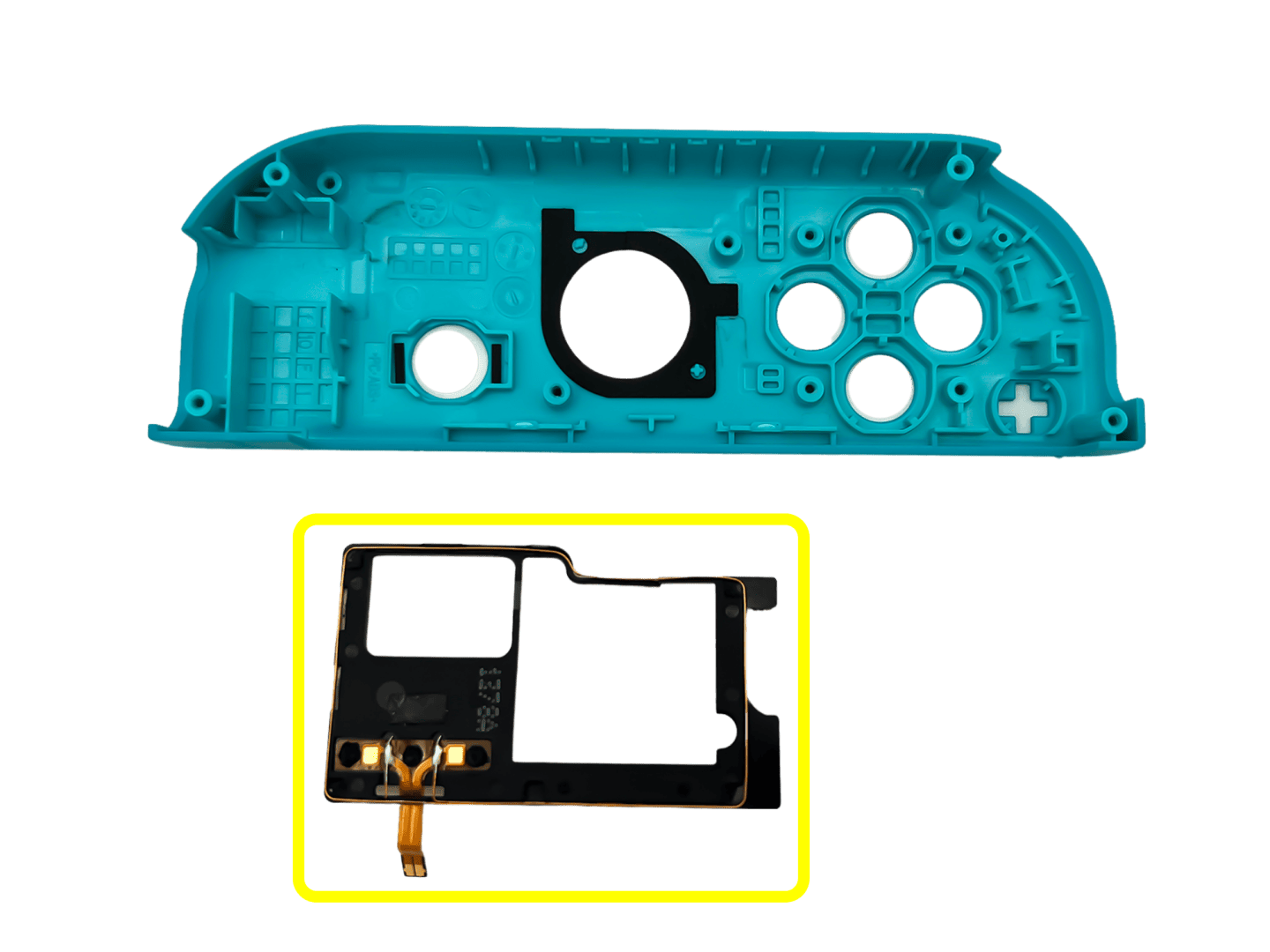

Utilizing a coaxial cable to move the NFC antenna away from the thumbstick allows the NFC signal to be generated and received away from the potential interference by the metal case of the thumbstick and the copper pours of the PCB

Use of a Broadcom BCM20734 chip with integrated 2.4GHz transceiver (Bluetooth) in both controllers eliminates the need for an external antenna for communication between the Joy-Cons and the Switch console

Addition of a Cortex-M3 processor enables a direct connection and dedicated processing for the controller, LEDs, thumbstick buttons, IMUs, NFC, and image processing chip

Use of a dedicated TI BQ24072 chip helps manage lithium ion (Li-Ion) battery performance and enables switching between an external power source and the internal battery to reduce charge/discharge cycles which directly impacts Li-Ion battery life

Customization of the ST LD39020 digital rail to output a linear voltage of 1.8V enables the MCU to step down the voltage to 1.2V for use internally and for memory

Application of the small form factor for antenna winding creates an efficient use of space

Design of physical connector markings to serve dual purposes enables accurate assembly during manufacturing and ease of identification by the user

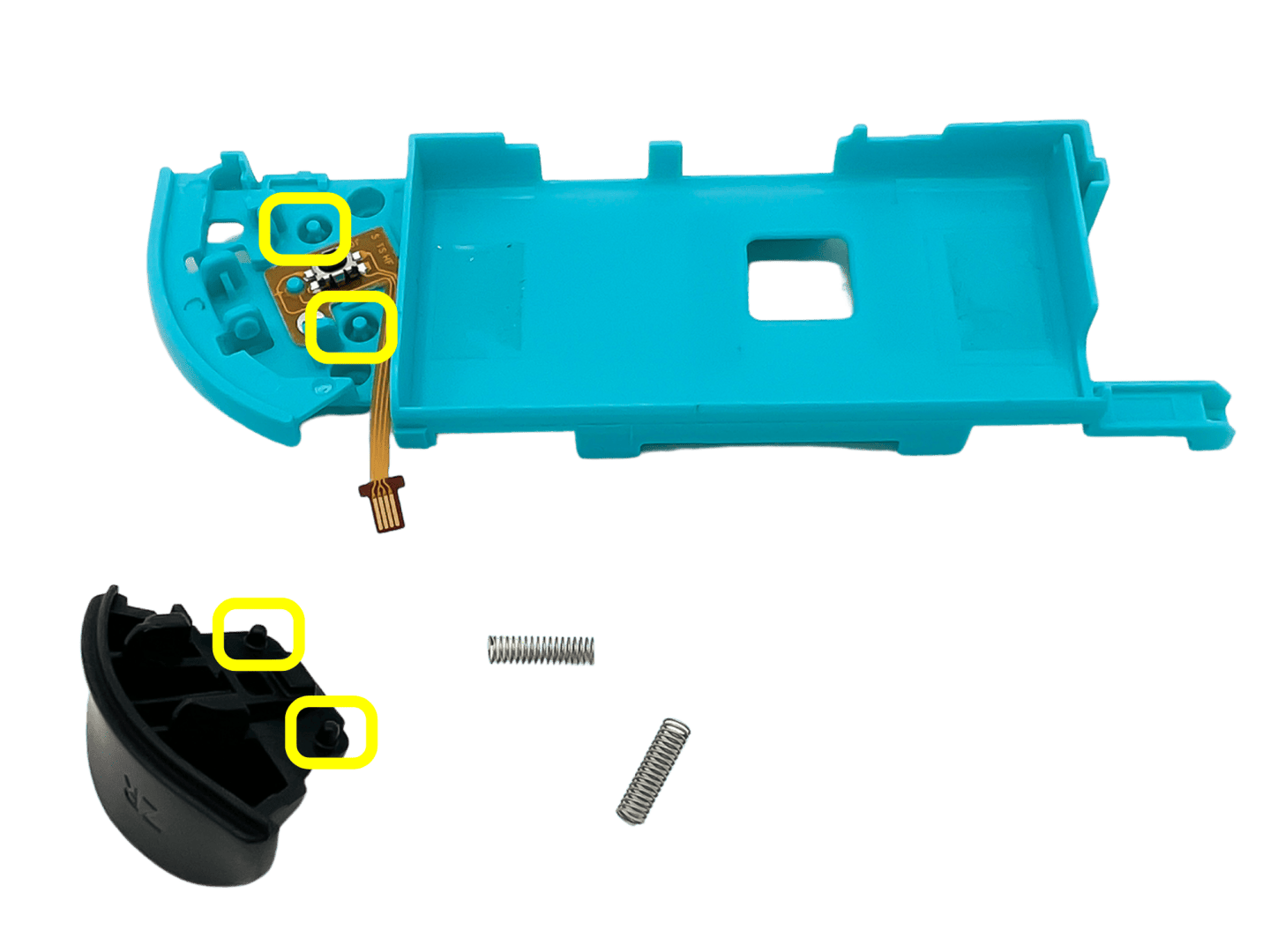

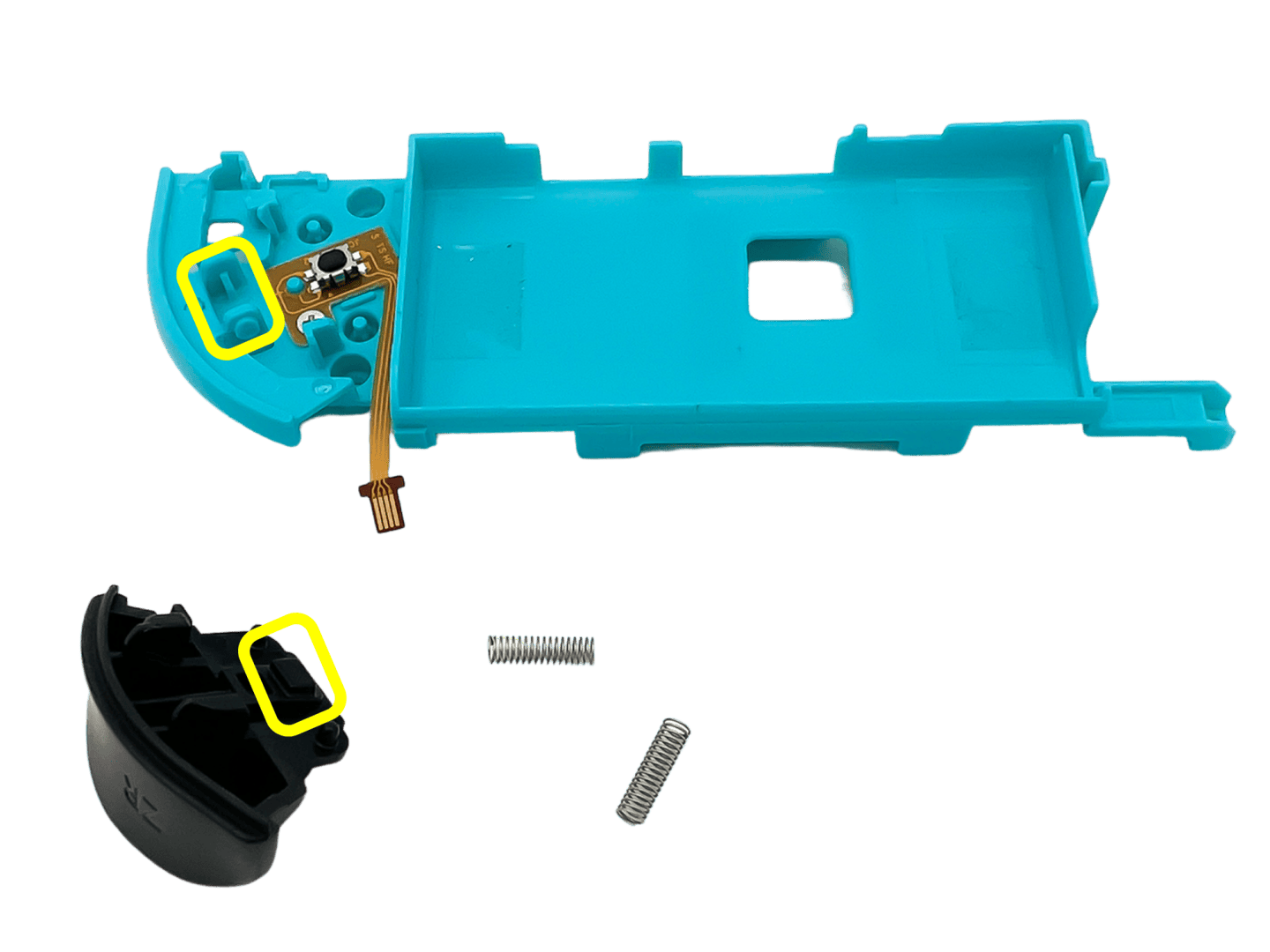

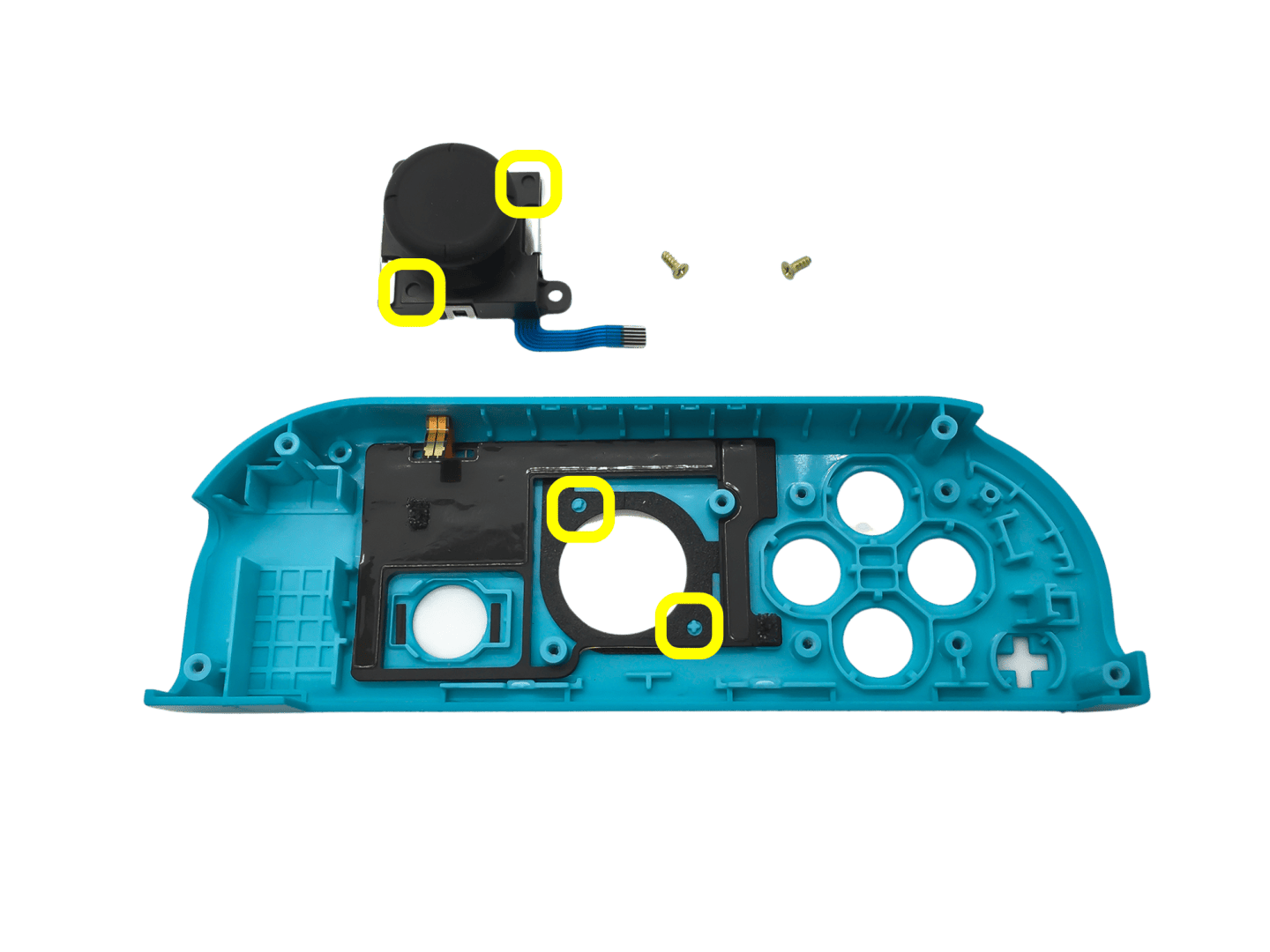

Addition of sheet metal reinforces and strengthens extremely small and fragile plastic parts

Supercharge Your Project with AC’s Integrated Engineering Teams

High Volume Product Development

As the global demand for the product development of consoles, games, platforms, controllers and accessories continues to increase year over year, it creates specific high volume challenges for design engineers. Even minor design issues can lead to major manufacturing bottlenecks. With new product introductions, developing a foolproof design is especially critical for high volume manufacturing so that parts can be quickly and easily assembled.

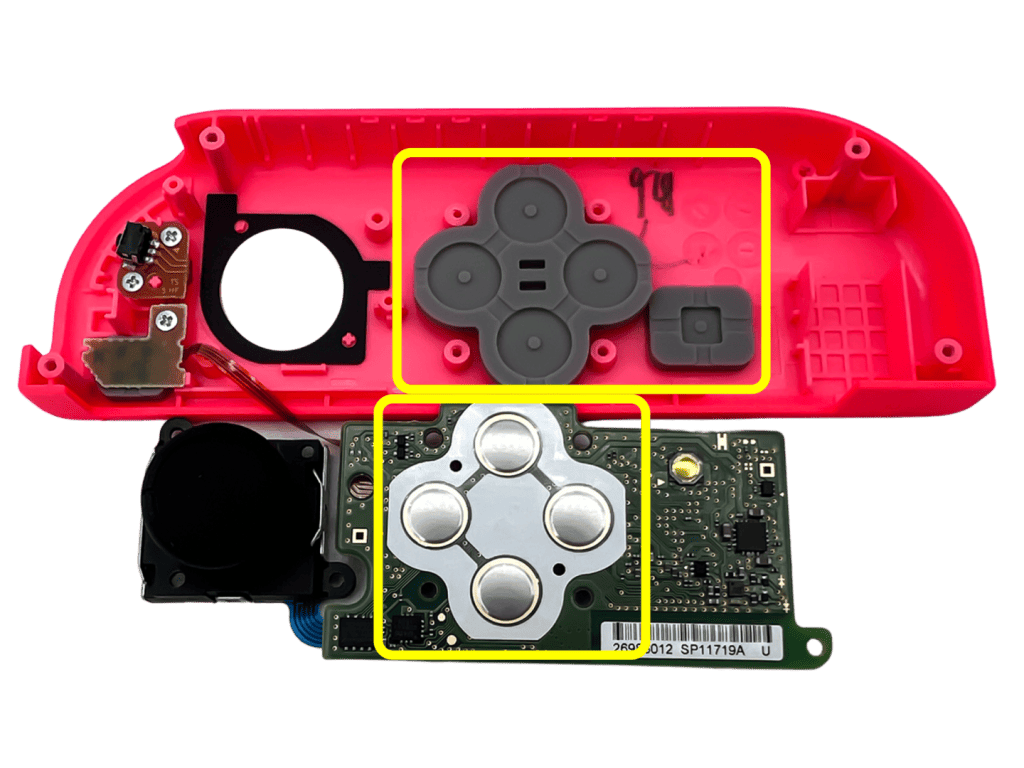

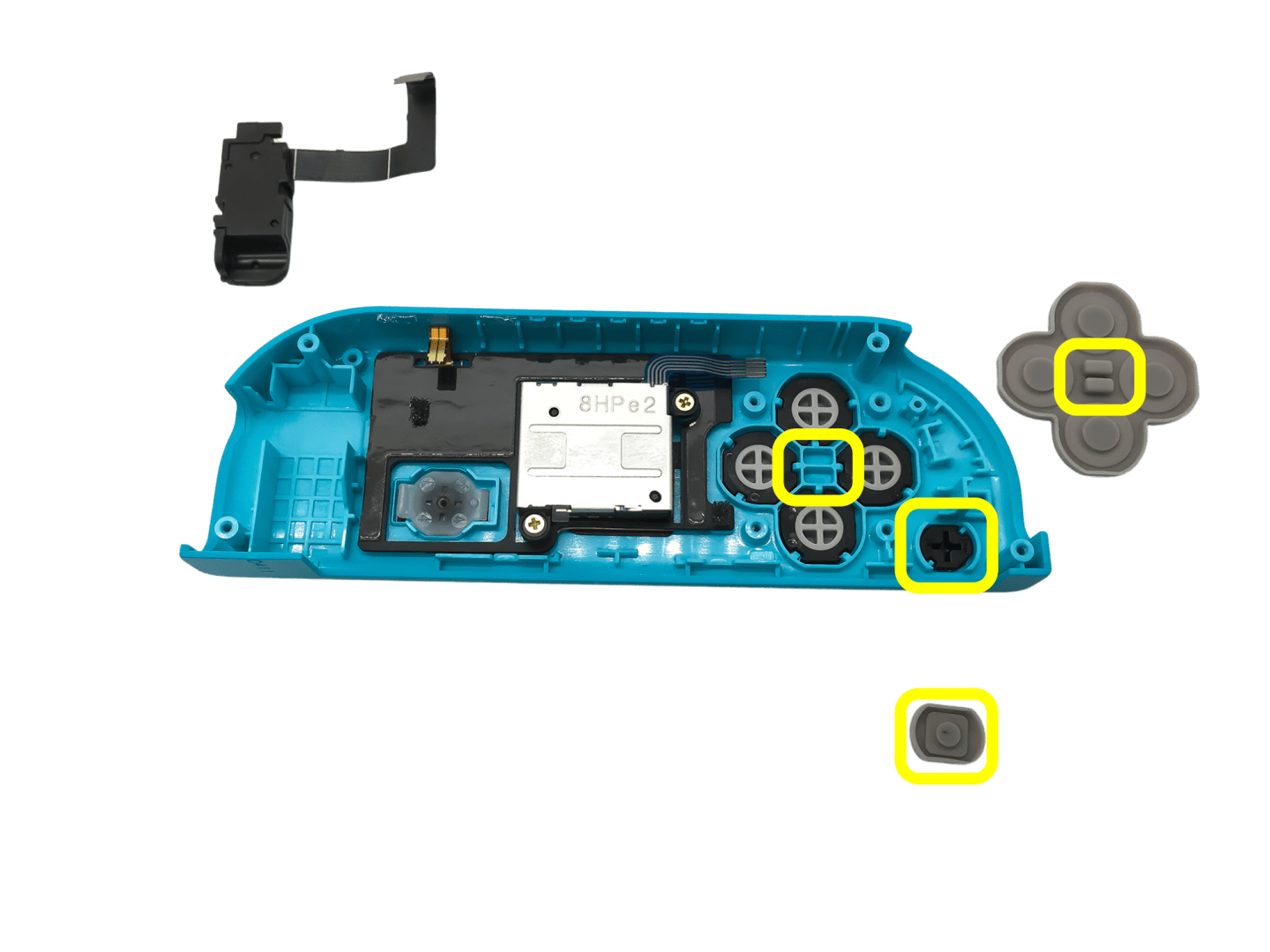

For example, dome switches were selected as a more reliable design choice for the Joy-Cons. Because of the flexible nature of the FPC, the kind of carbon print style buttons that are used on the main rigid board would not have been reliably pressed into the FPC during manufacturing.

Other dome switches are also utilized under the heavily abused A, B, X, and Y user control buttons which are bolstered by durable rubber membrane keypads.

As High Volume Product Development is deeply tied to Design for Manufacturability, we dive deeper in the next section for both realms.

Design for Manufacturability

Manufacturability at high volumes is another central objective of product development engineering. Handheld electronics manufacturing requires practical, experienced design and planning through a multi-discipline approach.

Design for manufacturing should result in increased efficiency and accuracy during manufacturing while simultaneously preventing part damage, fitment issues, production delays, and other challenges that can quickly stack up. Because time is money on an assembly line, it’s critical to design with intent to enable faster production and lower manufacturing costs.

Our engineers noted several Joy-Con design decisions that illustrate the insights and techniques of designing for manufacturability:

Decisions that enable efficient assembly

Screws types and sizes are reused for both inner and outer assemblies which enables the manufacturer to use a single driver size, type, and torque setting for the same size screws

Parts are assembled in the same orientation and direction within both halves of the clamshell which creates efficient and fluid assembly steps

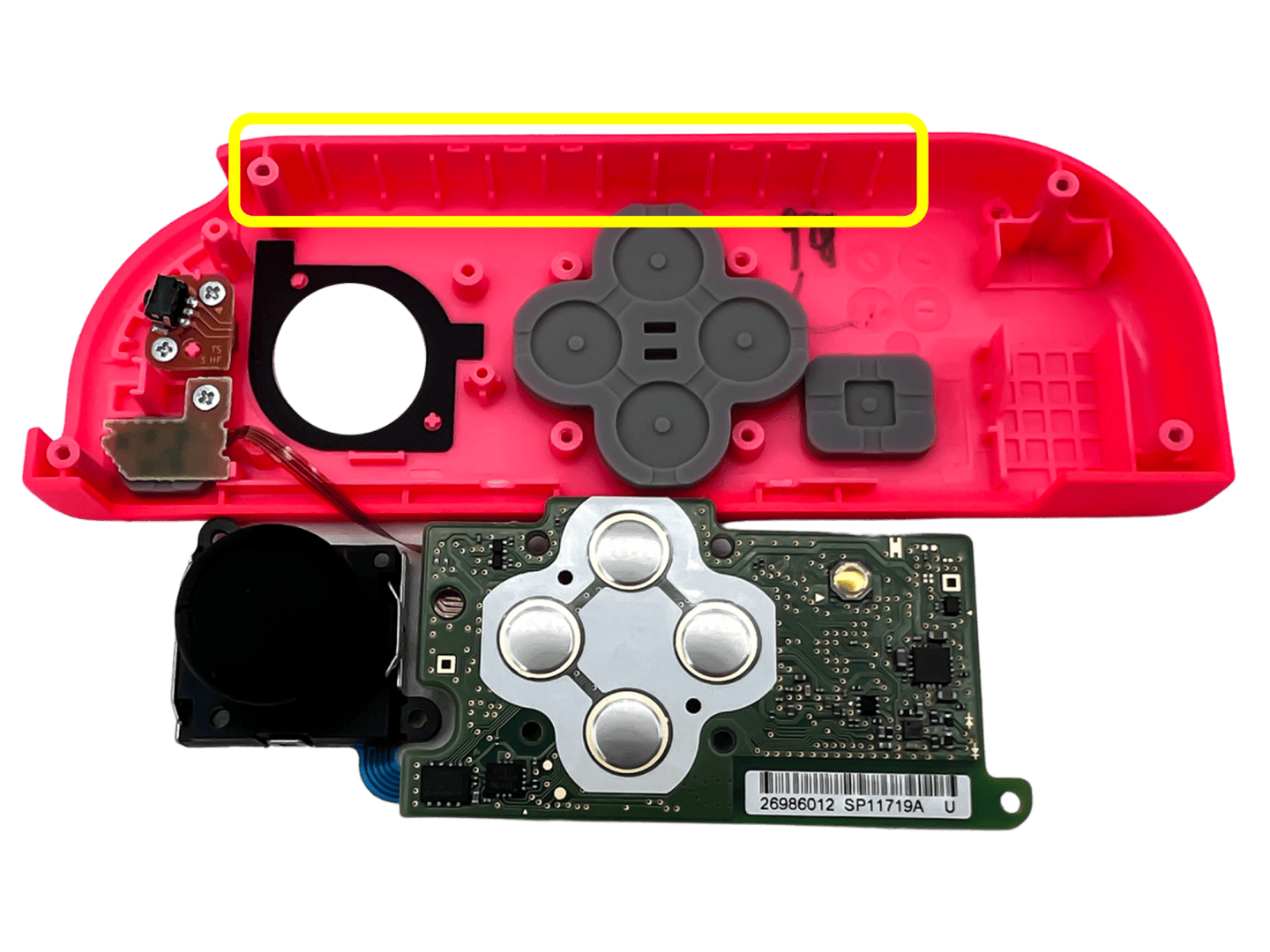

Ribbon cables that connect the two halves are oriented and sized in a way to allow the clamshell to safely fold closed during final assembly

Embedded features in the plastic help align, position, and hold components in place during assembly

Cables and wires are only as long as needed for a proper service loop that allows assembly, but not so long that they become cumbersome

Tiny plastic snaps along the long, unsupported edge keep the seam between the two case halves nice and straight, which is a design trick that provides for a much more consistent fit & finish in a high volume product

Smart retention features in the plastic reduce the number of parts on the BOM

Decisions that enable Accurate assembly

Built-in Poka-Yoke features and shapes (Japanese term for “mistake proofing”) ensure error-proof installation

Keyways and alignment features ensure correct and quick alignment between parts during assembly

What Nintendo Did Well

Stepping away from the teardown bench to reflect, we appreciate what an achievement it is to tackle dual system integration with a robust design that ensured manufacturing success at high volumes.

It’s worth noting that any finished design offers a fraction of insights about the total development effort. There are countless decisions that are made to ensure high volume assembly is reliable and with a low fallout rate, including analyzing tolerances and two-part interactions, just to name a couple. When you can’t spot the vast majority of the decisions during a teardown, it’s further evidence the engineers have done their job well.

From this informed vantage point, it’s pretty easy to see how the well-executed Joy-Con design has been integral to the worldwide success of the Nintendo Switch console.

As with any great design, we’re always inspired. We hope you are too.

The AC Approach

AC takes a holistic approach to product development by incorporating design for manufacture and assembly as well as advanced development. Custom automation systems developed for R&D, DVE, test and manufacture enable AC to do the impossible with your technology.

Even if you have limited internal resources or are facing challenging design issues, you can ask the right questions and design past the biggest challenges that threaten to disrupt your ability to integrate manufacturing capabilities into product architectures. We know because that’s what we do for our clients facing similar design decisions and tradeoffs. Reach out today to connect with one of our experienced engineers.